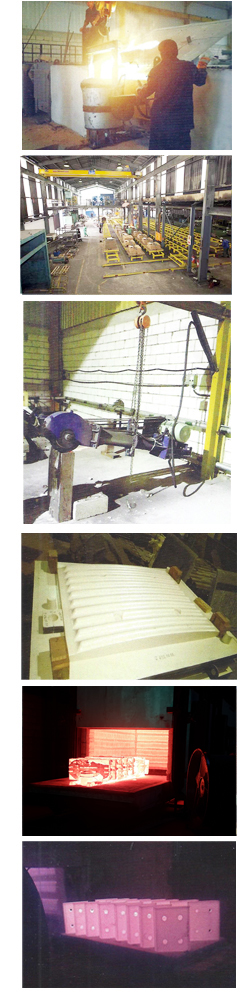

Infrastructure

Metal Casting Company has a state-of-the-art manufacturing facility at Vadodara. These facilities include ultra-modern machines and equipments that meet stringent international standards. The company is conscious about its responsibility towards environment. The manufacturing processes and machineries are environment friendly.

The products are manufactured based on client requirements. Right from raw material purchase to the finished products, client preferences and needs are factored on top priority.

Heat Treatment Department

Induction Furnace

Induction Furnace

- 1500 kg & 1000 kg melting crucibles with 900 KW medium frequency Induction Furnace , Make : M/S. ALIDIA POWERTRONICS (P) ltd., INDIA.

- LASSER type temp, measuring instrument, capacity 2000 deg. C

- Digital Pyrometers

Moulding Department

- Sand Mixer batch type : 300 kg/ batch

- Different sizes moulding boxes

- Pneumatic Ramming Machime

Pouring Department

Gear Wheel top pouring laddies with OET crane capacity 5T is 2000 kg, 1500 kg 1000 kg, 700 kg, 500 kg and 250 kg capacity ladles.Fettling Department

- Swing Frame Grinders

- Flexible Shaft Grinder

- 600 AMP. Rectifier Welding Machine

- Airscrew compressor 185 cfm ELGI Make

- Pneumatic Chipping Machine

- Pneumatic pencil grinder

Pattern Department

MCC Foundry has well equipped Pattern Shop available for development of wooden / aluminium patterns with or without match plates as per job specifications.Patterns are developed from drawings / samples provided by the customers.

Heat Treatment Department

- Solution Annealing, Hardening, Normalizing and Annealing - Heat Treatment

- Advanced technology Heat treatment furnace, 5 MT capacity batch type hearth bogie ceramic wool lining Electrically heated ( Kenthol heating element)

- 8 Point Temperature recorder with temperature 6 control system

- 5 MT Fork Lift Crane which can lift the material from the furnace and quench in the water within 45 seconds

- 300 Thousand liter capacity quenching water tank with automatic water circulator system with cooling towers for fast cooling of casting to maintain water temperature below 50 Degree C